Tel : +662 551-4578-9, +669 6978 9913

info@vigorpower.co.th

vigorpower.co.th

Pneumatic Boiler Tube Cleaners

for boiler & heat exchanger tubes

Air Motor

6000 series powerful short design of air motor is ideal for negotiating short radius bends when cleaning curved tubes. Precision slip-fit motor construction mean no special tool required for assembly and disassembly. Thrust plate motor packs plenty of power to operate all types of cleaning heads. Shown with forward swing arm type cleaner head and universal joint.

6300 series Thirst plate type motor specially designed for straight tubes motor parts slip-fit together for easy assembly without special tools. The motor operates at full power for high speed, heavy duty performance.

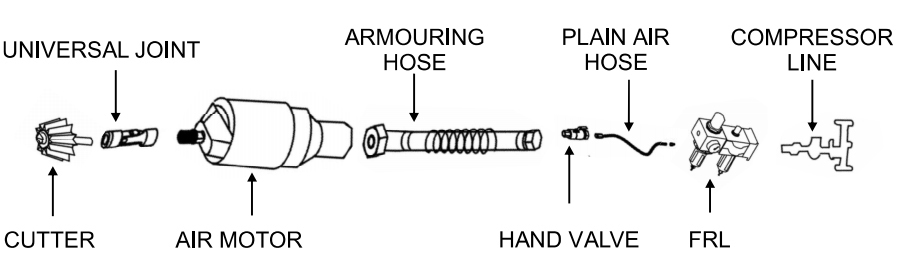

General Arrangement for Pneumatic Tube Cleaner System

Cleaning Accessories

Single cone Assembly

Assemblies consisting of one or two cone elements are used for cleaning straight tube size 1.1/8”-2.5/16”(28.60-58.70 mm)I.D. and curved tubes size 1.1/4”-2.3/8”(31.70-60.30mm.)I.D.

Double cone Assembly

Assemblies consisting of one or two cone elements are used for cleaning straight tube size 1.1/8”-2.5/16”(28.60-58.70 mm)I.D. and curved tubes size 1.1/4”-2.3/8”(31.70-60.30mm.)I.D.

Drill /Cone Assembly

for cleaning straight tubes plugged solidly with deposits.

Carbide Drill

used for cleaning straight tubes plugged solidity with scale or deposit.

Accessories for Turbine style Tube Cleaners

Armourd Hose

Armourd hose is connected between spiral steel wire winding throughout the hose length.

Plain Hose

It is located between hand valve,FRL/Compressor line. Standard length of plain hose is 10 meters.

Universal Joint

Universal Joint It is small tool connected between air motor and circular brush for vertical straight tube cleaning.

บริษัท วิกเกอร์ เพาเวอร์ จำกัด

Tel : +662 551-4578-9, +669 6978 9913

Email : info@vigorpower.co.th